Manufacturing is rapidly evolving, driven by precision and automation. At the heart of this transformation are Computer Numerical Controls (CNC) – machines that have revolutionized how products are made, from automotive parts to medical devices.

We’ve compiled a comprehensive list of the latest CNC statistics.

Here’s a breakdown of what you’ll find:

- Global CNC Market Share & Growth

- Key Industry Trends & Innovations

- Employment & Economic Impact

- And much more…

Let’s dive in!

Table of contents

- Top CNC Statistics (Editor’s Picks)

- How Big is the Global CNC Machine Market?

- Top Regions Driving the Most Growth for CNC Machining

- Which CAD Software Do CNC Users Prefer?

- What are the Top Types of CNC Machines?

- What are the Key CNC Components?

- How is Technology Changing CNC Manufacturing?

- Job Market Stats for CNC Tool Operators in US

- Salary and Employment Statistics for CNC Tool Programmers in US

- Who are the World’s Leading CNC Exporters?

- Who are the World’s Leading CNC Importers?

- How Much are CNC Machines Actually Being Used?

- How Much are Companies Investing in U.S. Machinery?

Top CNC Statistics (Editor’s Picks)

- The global CNC market size was USD 95.29 billion in 2024.

- Asia-Pacific held 55.32% of the global CNC market..

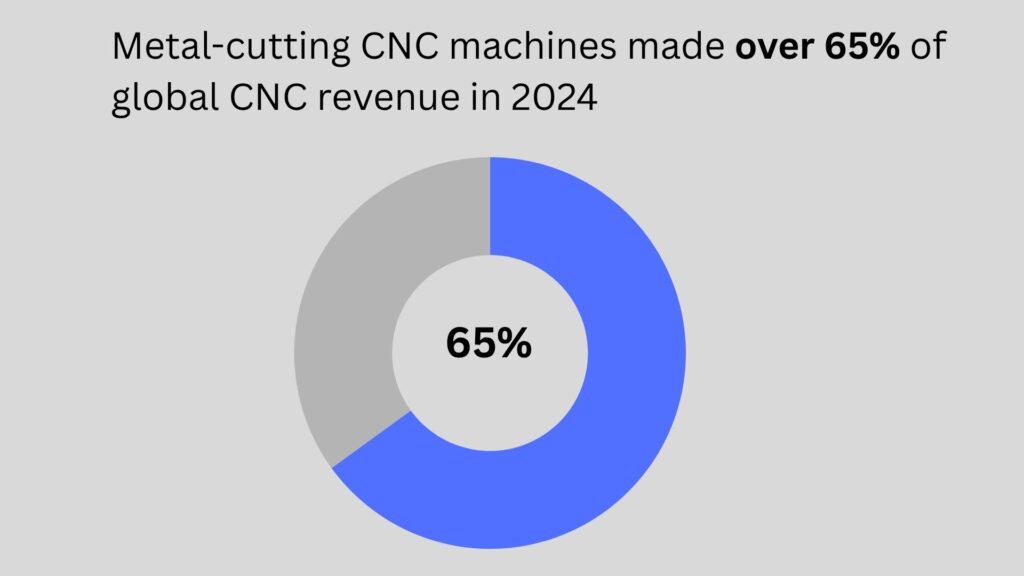

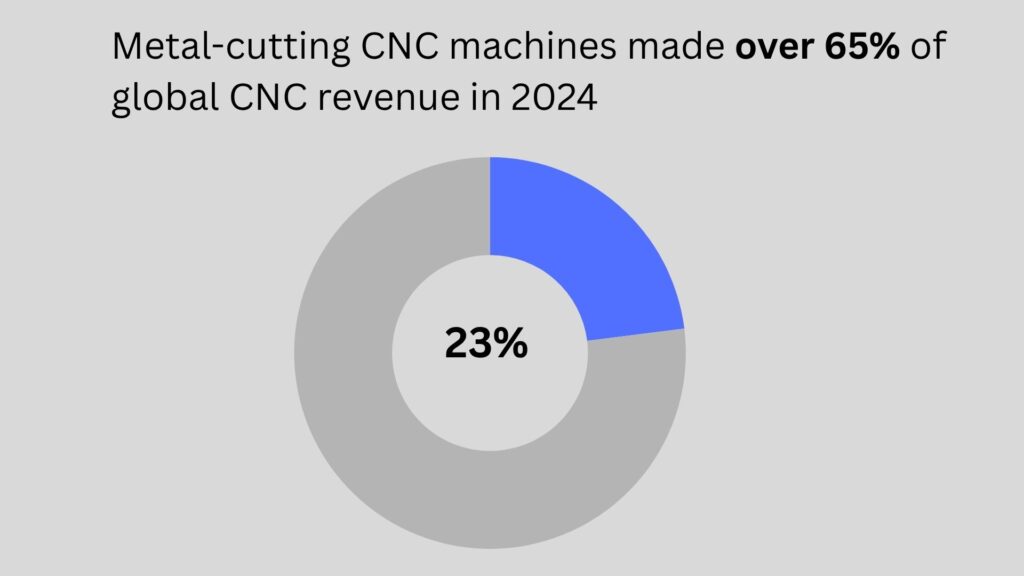

- Metal-cutting CNC machines made over 65% of global CNC revenue in 2024.

- Reports show average CNC machine utilization is only about 23.9%.

- According to survey, 51.5% of CNC users said they’re professionals (implying ~48.5% hobbyists).

- AI is reported to cut CNC cycle times by about 20%.

- The U.S. workforce included 187,670 Computer Numerical Control (CNC) Tool Operators as of May 2023..

- CNC tool operators in the US earned a mean annual wage of $51,030.

- CNC Tool Programmers earn even more, with a mean annual salary of $67,650. The top 10% make $94,880 a year.

How Big is the Global CNC Machine Market?

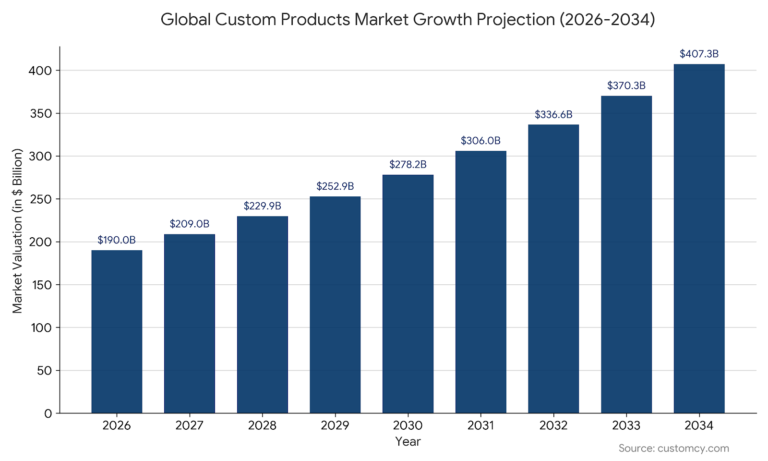

The global CNC machine market was worth $95.29 billion in 2024. This massive market is expected to keep growing quickly.

Experts project the market will reach $101.22 billion in 2025. One long-term forecast sees it hitting $195.59 billion by 2032.

This growth shows strong momentum. The compound annual growth rate (CAGR) from 2025 to 2032 is expected to be about 9.68%. Another forecast is even more aggressive, projecting a 9.8% CAGR through 2034.

Even focusing only on the core hardware, the market estimate is still $81.7 billion for 2025. The high-value control systems segment alone is estimated to be worth $108.63 billion in 2025.

Sources: Fortune Business Insights, PS Market Research, Mordor Intelligence, Archive Market Research, Market.us, Markets and Markets

Top Regions Driving the Most Growth for CNC Machining

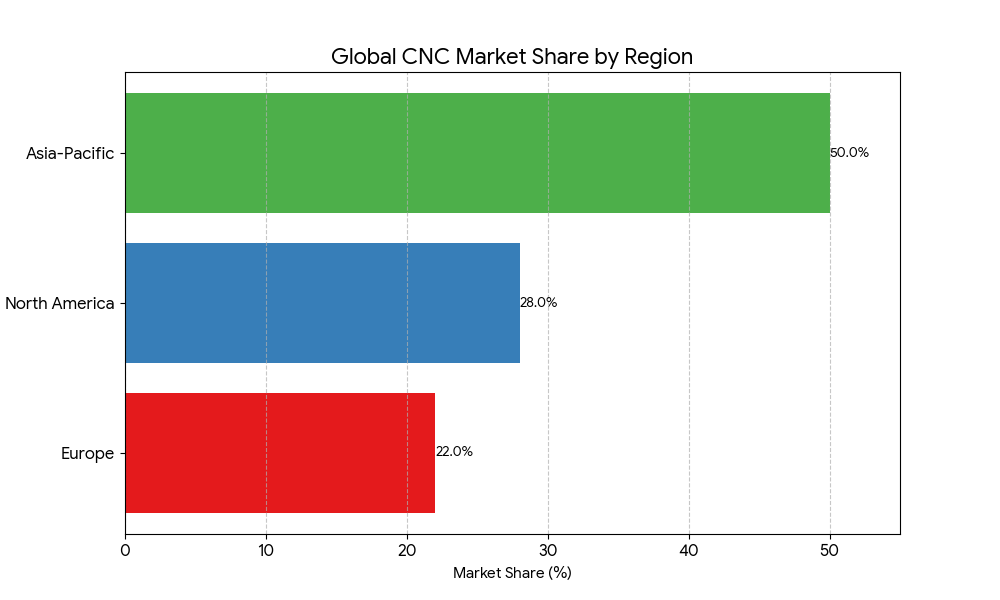

Asia-Pacific is the largest market, accounting for 55.32% of the global CNC market in 2024. The total value for the Asia-Pacific region was around $27.20 billion in 2024.

The growth rate in Asia-Pacific is very high, expected to show a 13.1% CAGR from 2024 to 2030.

Other regions also hold significant shares. North America is projected to hold a 28% market share in 2025. Europe is also a major player, with an estimated 22% market share in 2025.

Sources: Fortune Business Insights, Market.us, Grand View Research, Accio

Which CAD Software Do CNC Users Prefer?

The CNC Cookbook 2024 survey showed that Fusion 360 is the leading CAD package used in production. However, its market share fell slightly.

SolidWorks holds the second-place spot, gaining over 2 points of market share. This suggests SolidWorks is making a comeback against its main competitor.

When looking at user type, only 51.5% of respondents identified as professional CNC users, down from 55% last year. This trend shows an increase in hobbyist participation.

A significant 32.5% of users reported using a free, educational, or pirated software version, which is up from 25% in 2023. This indicates a growing reliance on non-paid software.

Rhino3D won the Gold Customer Satisfaction Award for having the highest user satisfaction. SolidWorks earned the Silver Customer Satisfaction Award.

Sources: CNC Cookbook

What are the Top Types of CNC Machines?

Metal-cutting machines dominate the market, making up over 65% of global revenue in 2024. Milling machines have the biggest market share of all machine types, with about 45% in 2024.

Lathe (turning) machines are the next biggest segment, holding around 23.4% of the market share. The total size of the CNC lathe market alone was $17.0 billion in 2024.

High-end machines are also growing fast. 5-Axis machining centers are projected to grow at a 6.09% CAGR from 2024 to 2028. Vertical Machining Centers (VMCs) will grow by $1.09 billion between 2025 and 2029.

Smaller, specialized markets are also valuable. CNC routers reached $691.0 million in 2023, and portable CNC machines were worth $214.8 million in 2023. By 2034, there are projected to be over 2.8 million installed CNC units worldwide.

Sources: Fortune Business Insights, SNS Insider, Mordor Intelligence, Precedence Research, PR Newswire, PR Newswire, Grand View Research, Next MSC

What are the Key CNC Components?

The core hardware is also a major business. The CNC controller market was valued at $3.2 billion in 2023. These controllers make up about 41% of the total CNC machine market value.

The smallest component parts are growing too. The market for servo motors is projected to grow at a 9.5% CAGR through 2030.

Sources: Allied Market Research, Mordor Intelligence

How is Technology Changing CNC Manufacturing?

New technology, like Artificial Intelligence (AI), is making production much faster. AI can reduce CNC cycle times by about 20%. It also shrinks programming time from about 16 minutes to just seconds.

CNC machines are also becoming greener. Optimized designs can cut energy consumption by up to 20%. Combining hybrid CNC with additive manufacturing can reduce material waste by roughly 15%.

These advances are popular, too. Google search interest for “advanced CNC milling machines” spiked to 100% in March 2025. Companies are setting targets to reduce scrap and waste by 15–25% through sustainability programs.

Job Market Stats for CNC Tool Operators in US

There were 187,670 CNC Tool Operators employed in the U.S. as of May 2023.

The mean annual wage for these operators was $51,030 in May 2023, which is about $24.54 per hour.

The industry with the most operators is Machine Shops, employing 40,520 workers at a mean annual wage of $50,440. Aerospace Product and Parts Manufacturing employs 13,410 workers, and pays the highest average wage at $61,040 per year.

The state of Ohio has the highest number of employed operators, with 21,960 jobs. The highest paying state is Washington, where operators earn an average of $81,050 per year.

Sources: U.S. Bureau of Labor Statistics

Salary and Employment Statistics for CNC Tool Programmers in US

CNC Tool Programmers earn a high salary, with a mean annual wage of $67,650 as of May 2023. The highest earners in this field (top 10%) can make $94,880 a year.

The total national employment for programmers is 28,030 workers. The Machine Shops industry has the most programmer jobs, with 5,600 employed.

Aerospace Product and Parts Manufacturing is the top-paying industry for programmers, with a mean wage of $87,470. The state of California has the highest number of programmers with 2,980 jobs.

Sources: U.S. Bureau of Labor Statistics

Who are the World’s Leading CNC Exporters?

Global CNC machine exports totaled 7,701 shipments between June 2024 and May 2025, which is a 9% increase year-over-year. The top three global exporters are China, Japan, and South Korea.

China led exports with 10,654 shipments, followed by Japan with 7,331 and South Korea with 3,045 total shipments. There are over 2,418 active CNC milling machine suppliers worldwide.

China has 747 milling machine suppliers exporting, and Vietnam is next with 685 suppliers. The U.S. has 66 CNC milling machine suppliers exporting, with HAAS AUTOMATION INC accounting for 31% of U.S. shipments.

Sources: Volza, Volza, Volza, Volza, Volza, Volza, Volza

Who are the World’s Leading CNC Importers?

The top three global importers of CNC machine tools by shipments are the United States, India, and Russia. The U.S. leads with 12,712 total shipments.

India follows with 3,579 shipments, and Russia ranks third with 3,464 shipments. The U.S. mainly imports CNC machine tools from China, Italy, and Germany.

One specific dataset showed the U.S. imported 104 shipments of CNC machine tools between November 2023 and October 2024. This represented a 1% increase over the previous year. Chinese CNC machines still face up to 25% tariffs under Section 301 of the Trade Act.

Sources: Volza, CNC Machines, Volza

How Much are CNC Machines Actually Being Used?

The average utilization for CNC machines was only 23.9% in the fourth quarter of 2022. This means machines are sitting idle most of the time.

Typical monthly utilization generally ranges between 22% and 30%. The lowest utilization is usually around 4:00 AM.

Machine use tends to decline over the weekend. Mid-week (Tuesday–Thursday) shows the highest utilization. Companies with the best performance can push utilization into the 60% range.

Sources: Machine Metrics

What are the Forecasted Job Needs and Industry Investment?

The U.S. manufacturing industry is struggling to find workers, projecting about 1.9 million unfilled jobs from 2024 to 2033. Employment for traditional machinists and tool and die makers is expected to decline by about 2% from 2024 to 2034.

Even with the decline, there are still about 34,200 annual openings projected for machinists and tool and die makers. Meanwhile, U.S. mergers and acquisitions (M&A) in precision manufacturing saw a +10% YoY surge in early 2025. Shops with high automation can trade at 10–12× EBITDA, much higher than the average 6–8×.

Sources: AMFG, Bureau of Labor Statistics, Focus Bankers, First Page Sage

How Much are Companies Investing in U.S. Machinery?

U.S. businesses are buying a lot of new equipment. New metalworking machinery orders in August 2025 totaled $529.4 million.

This monthly order volume showed a huge jump of +36.2% from July 2025. Year-to-date (YTD) orders reached $3.44 billion through August 2025.

This YTD figure represents an increase of +18.3% compared to the same period in 2024. For small-scale job shops, the average order value was the highest since August 2011.

One major growth area is construction, which made the largest order for manufacturing tech since September 2012. However, the aerospace industry saw a dip, with orders falling 20% month-over-month in August 2025.

Sources: AMT Online, AMT Online

Conclusion

These computer numerical control statistics show that Cthe NC industry is a rapidly expanding global force, with a market valued at nearly $100 billion. While job roles for operators and programmers are critical and well-paid, future growth will be driven by high-tech advancements like AI and concentrated heavily in the Asia-Pacific region.